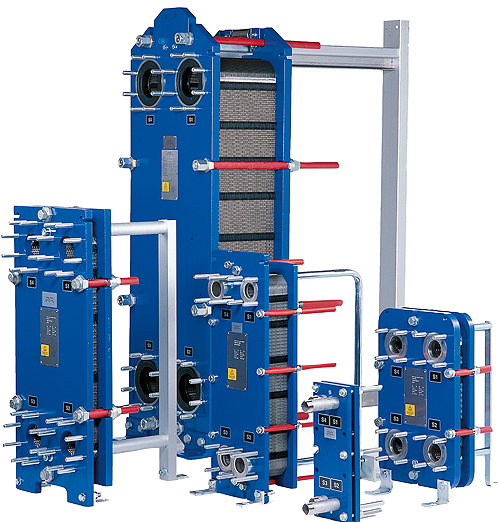

Plate coolers and heat exchangers

Cooling milk uses a significant percentage of a farms electricity costs. The advantage of using a plate cooler is to lower the milk temperature before it enters the milk tank.

By using bore hole or mains water, we can reduce the temperature of the milk from around 37 degrees down to 18 – 20 degrees in a single pass. This can only be achieved with the correct setup.

We now have 18 degree milk hitting the tank which has effectively more than halved the cooling capacity needed by the tank. This means reduce run time, smaller equipment needed to do the same job and improves the longevity of the equipment. This all adds up to massive energy savings just by having the correct setup.

If your milk isn’t entering the milk tank at around 20 degrees there are lots of ways to improve efficiency!!!!

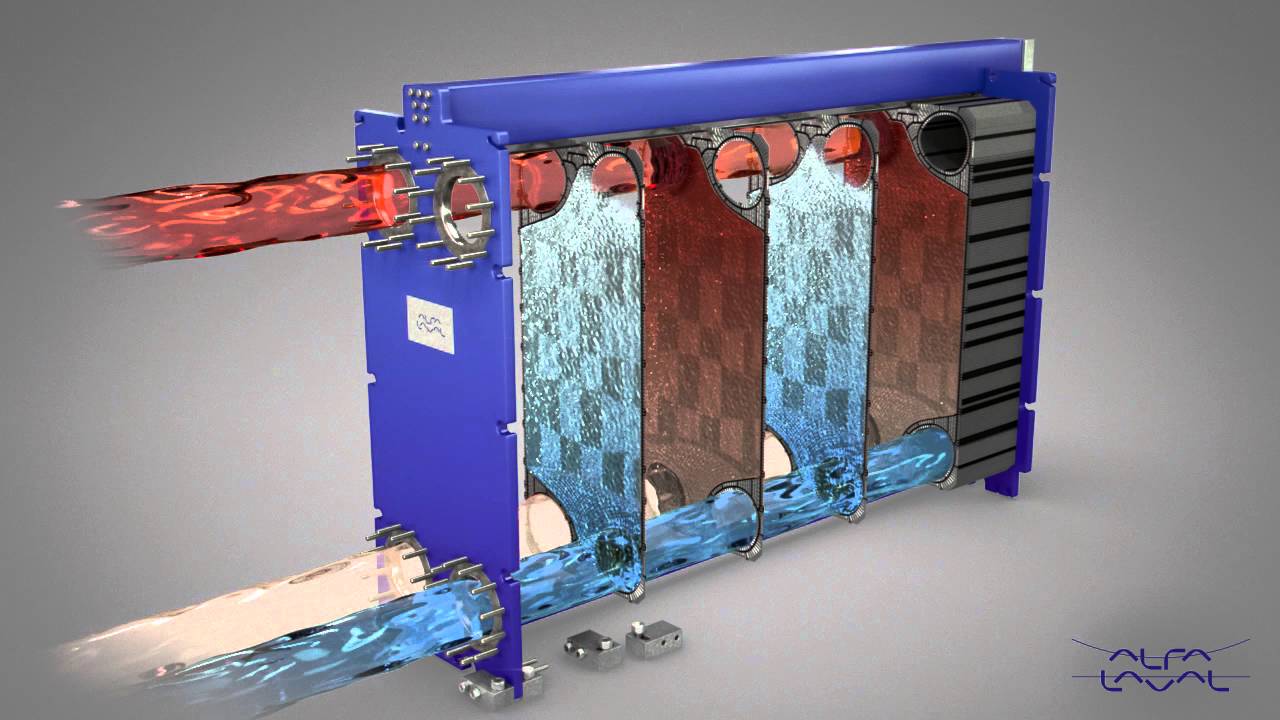

The process below shows how milk is pre cooled before entering the milk tank or silo.

Milk in dark red enters the plate cooler at 37 degrees passing through a network of honeycombed stainless steel plates. One the opposite side of the stainless steel plate we have our cooling medium water in dark blue. The heat is transferred from the milk to the water via induction.

- Correctly sized plate coolers with the correct water flow rate severely reduce energy cost

- It’s cheaper to cool your milk with water rather than electricity.

- Half the run time for your milk tank compressors

Ideally a ratio of 2:1 (2 parts water to 1 part milk) is needed. This maximises the amount of heat transfer from milk to water. The mains or bore hole water is then reused to supply drinking water for cattle and water for volume wash down systems. Check out our water handling solutions

We can further reduce the milk temperature by having another plate cooler, or by fitting one combi plate cooler which accepts bore hole water for pre cooling, and ice water for secondary cooling.

The secondary cooling is water from and ice bank. Ice is generated overnight when electricity costs are lower. This means the milk tank compressors have less to do in the daytime, there is also a benefit of having the milk hit the tank at around 4 degrees so it can be picked up at anytime.